Introduction: India has a long tradition of floriculture with flowers forming an integral part of almost all the religious, social and cultural activities of the Indian society. Jasmine is one of the most important commercial traditional flower crops of South India. In the recent past, export of the traditional group of flowers, particularly, jasmine and tuberose has picked up because of their increasing demand from the Indian population settled in foreign countries. Tamil Nadu is the leading producer of jasmine in India and the flowers produced in the state are being exported not only to the neighbouring countries viz., Singapore, Malaysia, Sri Lanka and the Middle East countries but also to distant nations including the United States.

Stringed flowers of J. sambac (Gundumalli) and J. grandiflorum (Pitchi) have shown to possess good export demand in the overseas markets wherein they are used for various purposes viz., making garlands and bouquets, adoring hair of women, religious offerings, marriage decorations, etc.

The major mode of transport of these flowers for export is by air and the flowers reach the Dubai and Singapore markets within 24 hours after harvesting, while it takes around 36 – 48 hours to reach the New York market. High levels of post harvest losses (35 to 40%) have been reported during transit. Since jasmine flowers are very delicate, they show signs of wilting with an abrupt loss of fragrance within 24 -36 hours after harvesting. One of the major problems faced by exporters is the lack of a proper packaging technology for export. Whenever there is delay in sending the flowers due to flight cancellations, the exporters face heavy losses, because the flowers cannot be preserved beyond a day. Since the flowers retain their freshness only for a day in ordinary packaging, any packaging technology that would extend the post-harvest life of flowers for even few hours would definitely benefit the exporters.

NAIP intervention: Keeping in view of the increasing demand for the fresh flowers as well as the need for the development of a reliable export packaging technology that would cater to the near and far overseas markets, an export packaging technology has been standardized for jasmine flowers under the ICAR-NAIP sponsored project ‘Value Chain on Flowers for Domestic and Export Markets’, in collaboration with a successful flower exporter, M/S. Vanguard Exports

The technology standardized is described below.

Export packaging technology for Dubai market: The jasmine flowers are collected from the auction centers and then loose flowers are made into strings with different shape and size based on the requirement of the buyer and this jasmine strings are treated with floral preservatives (Boric acid @ 4%) to preserve the freshness of the flower and improve the shelf life of jasmine strings. The treated jasmine strings are packed in ventilated corrugated fibre board (CFB) boxes with butter paper lining and the ventilation is made by making holes in the corrugated fiber boxes. After proper packaging the boxes are airlifted to respective destination.

|

|

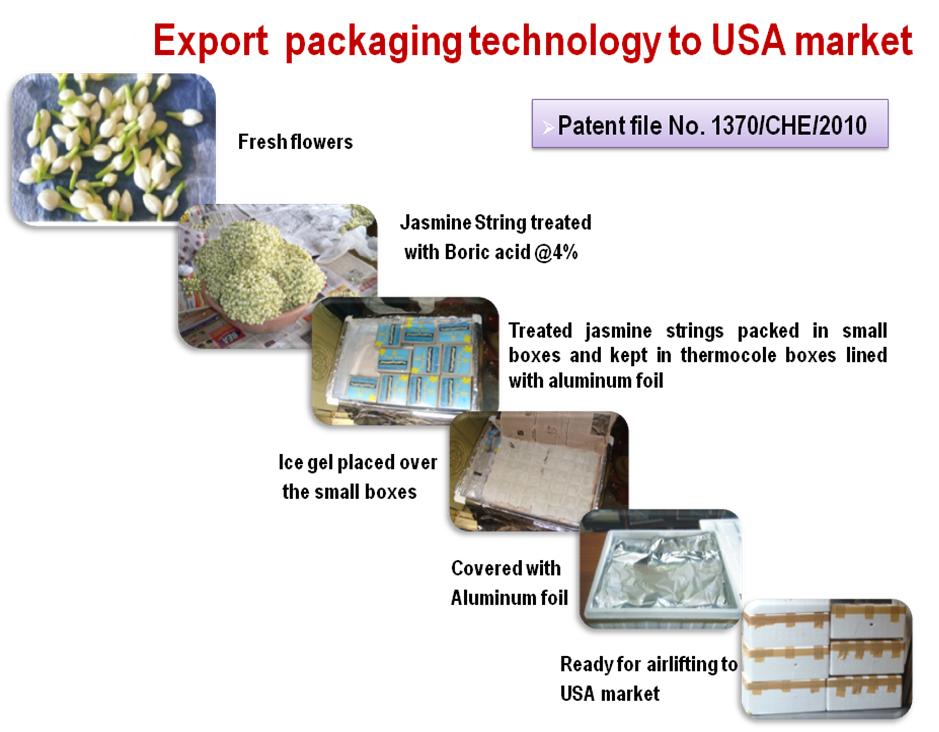

| Export packaging technology for USA market: Jasmine flowers are collected from auction centers and loose flowers are made into strings and related products. Stringed flowers of jasmine are treated with 4% boric acid and packed in aluminium foil lined light weight cardboard boxes. These boxes in turn are packaged in large thermocole boxes with intermittent ice gel packs to maintain the temperature and humidity inside the box. These thermocole boxes are transported in refrigerated vans to airport and then it is dispatched to the respective destination. |

| |

| Fresh flowers |

|

| Jasmine flowers made into strings |

|

| Jasmine strings treated with floral preservative |

|

| Treated jasmine strings made into 1 foot string |

|

| 5 Nos. of 1 foot strings packed in aluminium foil lined small boxes |

|

| 24 No. of aluminium foil lined small boxes packed in Thermocole (TC) boxes with butter paper lining |

|

| Airlifting to USA |

|

|

|

Dissemination of the technology: The export packaging technology developed was disseminated to jasmine growers and entrepreneurs through training programmes and demonstrations. A total of 1280 Growers and entrepreneurs were trained through 26 training Programmes

Impact of the technology

- Shelf life of flowers increased to 72 hours against 36 hours in normal packaging system.

- Instead of shredded ice packed in polythene cover, use of “ ice gel sheets ” in between the layers of small boxes reduced the weight and volume of the packages of export. The use of ice gel sheets in the boxes creates a low temperature (4 to 160C; 40C during packaging and 160C during unpacking at destination) and uniform distribution of chillness and moisture in the packs helps in increasing the shelf life of flowers.

- Post harvest losses were reduced from 40% to 10% and the export volume increased to 1000 kg/ day in 2013 (100%) from 500 kg/day in 2008.

- Before NAIP intervention, the net profit gained was only Rs. 9,250/day, and after the intervention it increased to Rs. 17,500/day.

- For Dubai market, the export volume increased to 900 kg/ day (2013) from 600kg/day (2008) and the net profit hiked from Rs.2,250/day (2008) to Rs.9,250/day (2013)

- New jasmine exporters promoted – 6 Nos.

- Market linkage – Tamil Nadu Flower Growers’ Association, Sathyamangalam (3000 growers) was linked directly with jasmine exporters for marketing

|

Source:

Professor and Head

Floriculture and Landscaping

HC & RI ,TNAU,Coimbatore-3

|