|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fisheries :: Fish Culture |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shrimps Culture

India is endowed with a long coastline and hence offers scope for large exploitation of marine wealth. Till a few years back, fishermen in India were involving themselves in traditional marine fishing. In the seventies fishermen started concentrating on catching prawns more commonly known as `shrimps' due to high profitable return on the same on account of their export value. Brackish water prawn farming started in a big way during 91-94 especially in the coastal districts of Andhra Pradesh and Tamil Nadu. The estimated brackish water area suitable for undertaking shrimp cultivation in India is around 11.91 lakhs ha spread over 10 states and union territories viz; West Bengal, Orissa, Andhra Pradesh, Tamil Nadu, Pondicherry, Kerala, Karnataka, Goa, Maharashtra and Gujarat. Of this only around 1.2 lakhs ha are under shrimp farming now and hence lot of scope exists for entrepreneurs to venture into this field of activity. The following table gives the state-wise potential and present level of development. Statewise shrimp farming area and production in India

(Source: MPEDA, 2005) Shrimp species and their suitability Many factors must be considered when a farmer is deciding which species of shrimp he should culture. Due to its large size and high price, Penaeus monodon and P. indicus are generally considered for farming. It has also been seen that both these species are suitable for farming in Kerala's environment. Apart from these candidate species other commercially important species such as Metapenaeus ensis, M. monoceros, M. brevicornis, Penaeus semisulcatus and P. merguiensis are also potential species that can be grown in India. Another potential candidate species that is flooding international market is the White leg shrimp, Penaeus vannamei. Although the Government of India has not yet given sanctions to culture it in the country, many Asian countries have already started to culture this species. Advantages of P. monodon

Advantages of P. indicus

Advantage of P. vannamei

Selection for a suitable site is a critical activity and must be carefully determined before establishing of a shrimp farm. Site evaluation is not only undertaken to determine if a site is suitable for shrimp farming. It is also valuable in determining what modifications are needed concerning layout, engineering, and management practices to make shrimp farming possible at a given site. No site will have all the desirable characteristics, so a number of judgements have to be made for every site. There are several factors involved during site selection. Topography and Climatic Condition Topographically, the best areas for shrimp culture are those with average natural ground elevations of about 1-3 m above mean sea level or at least 1 m above the highest high tide level to allow drainage and harvesting. The cost of pumping increases in highly elevated sites. The sites should have minimum vegetative cover, be near the sea or other natural waterways such as rivers and streams, have easy access to roads, a sparse population and be nearly square or rectangular in shape. In terms of climatic conditions, areas having short and not as pronounced a dry season with moderate rainfall distributed throughout the year are the best suited for shrimp farming. A pronounced long dry season may cause an increase in water temperature and salinity, which will promote excessive growth of algae and result in oxygen depletion at night. Infrastructure Accessibility The farm must have good accessibility either by road or water, and communication systems throughout the year in order to facilitate supervision and transport of materials and products. It is important that the farm be within 3-6 hrs traveling time from the hatchery to avoid excessively long transportation time of the larvae and should be within 10 hrs from the processing plant to avoid deterioration of the product. Electricity Availability of relatively cheap and reliable power source is a major consideration in site selection. In areas where electricity supply exists, it is practical and beneficial to utilize electric power to run the farm, especially for the intensive culture system. It is advisable to have a back-up electricity generator as a secondary power source. Security Areas free from security risks result in favorable working conditions, productivity and less extra costs. Availability of Labor and Other Factors The availability of labor, equipment and commercial feed and supplies ensure smooth operations and successful crop. Water Supply Site should have good pollution free water supply of both freshwater and brackish water. Water quality parameters required for maximum feed efficiency and maximum growth of Penaeus monodon are given below:

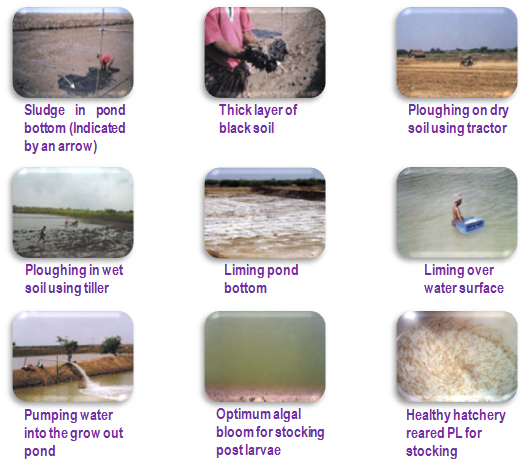

Water from polluted areas containing high concentrations of suspended solids and organic wastes such as effluent water from industry; urban areas, agricultural and other farm locales should be avoided. A settling pond or a large reservoir should be used in such areas for sedimentation and treatment. In saline areas, a source of freshwater is useful for adjusting the salinity in the ponds and for domestic use by farm staff. The freshwater should be good enough for use and adequate throughout the year. Soil Conditions The type of soil is the most critical in site selection, since the shrimp will spend most of their time on the pond bottom during the culture period. Usually, clay or loam-based soil containing more than 90% clay and pH between 6.5-8.5 is preferable. Sites with sandy or silty soil should be avoided due to their porous nature that may lead to erosion, seepage of water and easy infiltration of waste into the soil. Prior to construction of ponds, samples of soil should be taken randomly from 5-10 spots at the surface and at 1 meter deep and sent to a laboratory for the analysis of soil texture and pH. Such data will be useful during pond construction and preparation. Mangrove or acid sulfate soils are not suitable for shrimp pond culture due to their high organic matter contents and acidic nature that require a high water exchange rate and low stocking density. A pond built on mangrove soil will also encounter the problems of hydrogen sulfide and ammonia accumulation in the pond bottom. In the acid sulfate soil areas, the soil will develop high acidity when dried and then flooded which will lead to difficulty in stabilizing the pH of the pond water and in inducing the growth of plankton during the culture period. 3. Pond Design and Construction A shrimp pond should be designed according to the characteristics of the selected site and the culture system. There is no unique design, but optimum and functional farm layout plan and design should be based on the physical and economic conditions prevailing in the locality. Culture systems There are three types of shrimp culture being practiced in most countries. Traditional/Extensive Cultures The ponds have irregular shapes and sizes, mostly 1.5 ha and bigger with a peripheral ditch or canal of 4-10 m wide and 40-80 cm deep. The pond bottom may not be properly leveled, but tree stumps are usually removed, although this is not required. Ponds are normally filled with gravity flow water during the high tide period with natural seeds and left for 60-90 days, without additional seed stocking and feeding. Stocking density in this type of culture is 0.5-5.0 pcs/m2. These ponds are normally partially harvested. Semi-Intensive Culture Ponds of 1-1.5 ha in size and are constructed with dikes to hold the water 1-1.5 m deep. PL are stocked into the pond at 10-15 PL/m2 and fed with commercial diets and/or fresh diets. The shrimp are harvested at 90-120 days after stocking. Intensive Culture The ponds are usually of 0.5-1 ha in size and are designed to keep the water at 1.5-2.0 m deep. A reservoir of at least 30 % of the pond area is usually required. High stocking density of 25-60 PL/m2 with feeding rate of 4-6 times daily and strong aeration is maintained. Open System This system requires a high supply of good quality water because it needs a water, exchange of more than 20% of the total pond volume at one time, in order to reduce pond wastes and the density of the plankton. Seed can be stocked up to 60 PL/m2 and will grow to 25-35 grams within 120 days. The open system has recently become less favorable to farmers since the environmental conditions, especially the quality of water, tend to deteriorate with time. Re-circulation System In order to avoid deterioration of the environmental conditions, several advanced and company run farms have adopted the re-circulation system to minimize contact with poor quality water from outside the farm. However, the farm must devote 40-50 % of the area for the construction of water storage/reservoir, sedimentation pond, treatment pond and drainage canals. To operate the system, cleaned seawater is initially pumped into the pond and kept within the system. During the culture period, the effluent from culture pond is drained into the sedimentation pond, treated with chemicals and pumped into the reservoir for re-supply to culture ponds. The stocking density for this system generally varies between 30-50 PL/m2 and the culture period is between 110-130 days. Minimal Water Exchange System The majority of small farms cannot support space for construction of the water treatment pond and reservoir as in the case of the re-circulation system. To reduce contact with the water from outside the farm, the minimal water exchange system or closed pond system is practiced in some countries, particularly in Thailand. The system involves filling up the pond with cleaned seawater, treating it with chemicals to eradicate predators and competitors. Then the shrimps are stocked up to 30 PL/m2 and cultured for a period of less than 100 days to attain the average weight of 10-20 gm. Since the system does not require water exchange, but maintains the water level in the pond by replacing the water loss due to evaporation and seepage with seawater or freshwater, it can be operated anywhere, even in the inland area where seawater is not easily accessible. The disadvantages of this system are that it requires low stocking density and high efficient water and waste management. However, it is suitable for production of small size shrimp because the culture period is limited. Farm Design An extensive shrimp farm should be of the size 0.4 - 0.5 ha and preferably drainable from the management point of view. The ponds generally should have concrete dikes, elevated concrete supply canal with separate drain gates and adequate life supporting devices like generators and aerators. The design, elevation and orientation of the water canals must be related to the elevation of the area with particular reference to the mean range of tidal fluctuation. The layout of the canals and dikes may be fitted as closely as technically possible to existing land slopes and undulation for minimizing the cost of construction. Water Supply System A shrimp pond is filled with water mostly by pumping. The pumps should be installed at locations where they can obtain water from the middle of the water column with least sedimentation and pollution. The pumps and inlet canal should be large enough to allow the ponds or the reservoir to be filled within 4-6 hrs. A screen should be installed at the inlet canal prior to the pumps to prevent clogging at the inlets. Reservoir A reservoir is important for the control of pond environment and storage of water supply when the water quality is inconsistent or the supply is intermittent. It is recommended that the area of a reservoir within a farm should be about 30% of the total farm area in order to hold a sufficient volume of the water supply. Some farms may use part of the reservoir for sedimentation purpose where biological filter feeding organisms are stocked. The reservoir must have an outlet that can allow total drainage. Supply Canals An intensive shrimp farm should have a water supply canal to convey the water from the reservoir to the ponds by gravity or pumping. The size of the supply canal will depend on the size of the culture pond, the efficiency of the pump and the required water exchange rate. Ponds A well-designed pond will facilitate the management of water exchange, harvesting of the product, waste collection and elimination, and feeding. (i) Shape The shapes of pond that are found to be effective for shrimp culture are rectangular, square and circular. A well-designed pond is one that would allow circulation of the water such that wastes will be accumulated at the center of the pond. Some farmers improve the water movement in the square and rectangular ponds by making the corners of the pond rounded through addition of soil. (ii) Size Smaller ponds are easier to manage but the construction and operation can be costly. Ponds of 0.5-1.0 ha. are commonly used in intensive culture and 1-2 ha for semi-intensive culture. Dikes Earthen dikes, with or without lining, are found to be the most economical. Dikes should be designed to impound higher than 1 m depth of water and must be high enough to prevent flooding during the rainy seasons and the highest high tide. The slope of the dike depends on the nature of the soil. A slope of not less than 1:1.5 is normally used in the sandy soil area to avoid erosion and 1:1 is used for clay soils. One must be aware that shallow slopes will encourage the growth of benthic algae which will impair the quality of the water in the pond. Some dikes in a farm may be wider than the others to provide space for the access road, storage, electricity and aerators. Pond Lining Lining materials are used in pond where the soil contains a high percentage of sand, and organic matter and is acidic in nature. Lining can reduce erosion, water seepage, waste accumulation in the soil and the leaching of ammonia, hydrogen sulfide, acidic compounds, iron and other potentially stressful compounds into the ponds. The lining also allows easy removal of wastes from the feeding areas, reducing the time and costs to clean the ponds between cycles. Several lining materials are currently available. The economic life of liners varies according to the maintenance and the duration of exposure to sunlight. Among the liners, laterite soil is less expensive and commonly used in shrimp farms. However, laterite soil liner may allow the penetration of wastes and requires effective cleaning up. Pond liners with PVC plastic sheeting and geotextiles can reduce the cost for aeration and cleaning up due to the easy movement of wastes and uneaten food on the smooth surface. The disadvantages of PVC plastic and geotextile-lined ponds are difficulties in maintaining plankton bloom within the first month of culture, problem of tears and the floating of the liner if the water and gas accumulate underneath them. Gates for Inlet and Outlet Each shrimp pond should have at least one gate for filling and draining water. However, a typical pond of 0.5-1 ha usually consists of two gates having similar structure for the inlet and outlet gates. The size of the gate is dependent on the size of the pond, but must allow the pond to be filled or drained within 4-6 hrs. Gates of 0.5-1.0 m wide are usually constructed, since gates wider than 1 m will cause difficulty in screening and will allow strong currents which will cause erosion of the soil. The position of the outlet should be at the lowest point of the pond with a gradual slope of 1:200 from the inlet to allow total drainage of the pond during harvesting. The conventional gates constructed at the side of the pond should have a double screen, with fine a mesh for the initial period of culture and a coarser one for a later period. Some farmers may place both meshes in a single frame and cut out the finer mesh when the size of the shrimps are larger than the opening of the coarser mesh. Central Drain This has been employed in some farms and consists of perforated pipes laid horizontally at the center of the pond and connected to a pipe leading to the outlet. A screen of small mesh size is used to cover the drain for the first 50 days of culture and is removed to allow for easy removal of water when the shrimps are larger than the diameter of the pipe. This method has the advantages in that it can remove the waste and clean the pond bottom any time throughout the culture period. Drainage Canal and Sedimentation Pond The drainage canal of a shrimp pond should be at least 50 cm lower than the lowest point of the pond to allow drainage by gravity. The effluent will be drained into a sedimentation pond to settle the particulate wastes before water is pumped into the reservoir or released out of the farm. It is recommended that the sedimentation pond should be approximately 5-10% of the culture area and should be deep enough to prevent mixing and re-suspension of the wastes. Baffles or soft walls made of fine mesh net or plastic sheeting supported by stakes driven into the pond bottom, may be constructed in the sedimentation pond to decrease the velocity of water and increase the retention time which will enhance the settlement of the wastes. The wastes in the sedimentation pond should be removed periodically and discharged into the waste dumping area. Waste Dumping Area A shrimp farm should provide 5-10% of the area for dumping of the wastes. Wastes from the pond must be collected carefully and dumped into this area without discharging to nearby areas, which will contaminate the natural resources. Buildings Accommodation, storage, shop and guardhouses may be built in the farm as required. It is advised that accommodation for workers should be set up at various points around the farm for security purposes and to allow the ponds to be adequately monitored. Pond Preparation Before a pond can be stocked for a new crop, the excessive wastes, which accumulate in the pond during the previous crop, must be removed and the soil and water conditioned. Growing of shrimp in an improperly prepared pond may lead to difficulty in pond management during the culture period, which could result in a decrease in production capacity of the pond. Pond Cleaning The cleaning of a pond or removal of the wastes, especially the organic and phosphatic wastes that have accumulated in the pond bottom could be, accomplished by drying, liming and ploughing. However, these methods could still leave an adverse effect on the water and soil quality in the pond, which could result in a decrease in the production capacity of the pond. There are two methods for cleaning a pond according to the possibility of the pond to be dried: Dry Method This method is used when the pond bottom can be dried completely. The pond is drained and left to dry in the sun for a period of 10-30 days. Then the waste is removed, either manually or mechanically, and transported to the waste dumping area. Removal of waste by machines has an advantage that it can compact the bottom soil. However, this cleaning method by drying may lead to development of acidity, lowering the level of the pond bottom and the diffusion of wastes if the workers are inexperienced. Wet Method In areas where the pond cannot be dried completely, pressure washing can be used to flush out the wastes. This method takes a shorter time and is more efficient than the dry method. Flushing should be continued until the acid and dark anaerobic layer in the soil are removed. This method is suitable in the acid sulfate areas where the oxidation of the soil must be avoided. However, the method requires a sedimentation pond to all settlement of the suspended wastes to avoid contaminating the drainage canal and the natural environment. The remaining pathogens in the ponds can be eliminated during the liming process. Liming Once the pond is cleaned, it is then filled with water and left overnight before flushing out to remove debris and elevate the pH. This process should be repeated until the pH of the water remains above 7, and only then the lime is applied. The types of lime to be used depend on the water pH. It is recommended that agricultural lime (CaCO3) or dolomite [CaMg(CO3)2] should be used in a pond with water pH near neutral and the hydrated lime [Ca(OH)2] should be used in a pond with water pH below 5. The amount of lime to be used should be carefully calculated to avoid inducing an excessively high water pH, which may increase ammonia toxicity and result in the mortality of the shrimps. The lime requirement of a pond depends on the soil pH. The measurement of the soil pH should be determined either by the wet soil method or by the dry soil method. During the application, lime should be spread throughout the pond bottom and up to the top of the dike. A large portion of lime should be applied over the feeding areas and to all parts of the pond that have remained wet. When the pond is properly limed and filled with water, the average water pH should be between 7.5-8.5 with daily fluctuation of less than 0.5. Agricultural lime, dolomite or hydrated lime at 100 kg/ha/day should be added to maintain the required pH. Eradication of Predators After liming, the pond should be filled to the maximum depth through a screen with fine mesh to prevent the predators and competitors from entering the pond. These animals, including fish, crustaceans and some invertebrates, may compete for food, prey on the shrimp or carry diseases and parasites. They may establish themselves in the pond that is not effectively screened effectively or is left for a long period of time. Some chemicals should be used to eradicate these animals in the pond before stocking. Fish can be killed by the application of tea seed powder at the rate of 20-30 ppm. After the application of tea seed, the pond should be left for 3 days before the post larvae can be stocked. Tea seed may also be used when the shrimp has reached a weight of more than 2 gm. However, it must be remembered that tea seed is more toxic at high salinity and temperature, but less toxic at high pH. Application of tea seed in the evening may reduce pH and result in plankton die-off. Snails can be eliminated by the application of quick lime (CaO) at 530 kg./ha and sun dried for 2-3 days. Then the pond should be thoroughly cleaned, filled with water and the other pests eradicated. Hypochlorite, either calcium or sodium salt, is currently used at 15-20% (60% active ingredient) to eliminate both vertebrates and invertebrates. The pond must be cleaned prior to the application of hypochlorite since hypochlorite may react with the organic matters and produces the toxic organochlorine compounds. Hypochlorite should be applied after the pond is filled to the maximum height and left for 3 days to allow the hatching of planktonic organisms. It should be remembered that hypochlorite should be used prior to the liming since the effectiveness of hypochlorite will be lowered in high pH conditions. After the hypochlorite application, the pond should be aerated and the application of lime and fertilizer should be conducted on Day 3, while the PL can be stocked on Day 7. During the first month, water must not be added to the pond, unless the water quality is poor, to prevent the introduction of competitors and predators. Fertilization The pond must be fertilized with either organic or inorganic fertilizer to stimulate the plankton bloom in order to provide shade to the pond bottom and utilize the nitrogenous and phosphate wastes within the pond. The shade will also prevent the growth of harmful benthic algae. The sun dried chicken manure is the most common organic fertilizer to be used in the amount of 200-300 kg/ha. The manure must be soaked in water for 24 hours before it is spread over the surface of the water. Inorganic fertilizers, such as urea (46% N) and compound fertilizers like, ammonium phosphate (16:20:0) or those with N:P:K combination of (16:16:16) can be used at 20-30 kg./ha. The fertilizer must be dissolved in water before it is spread over the water surface to avoid precipitation of the fertilizer onto the pond bottom, which will enrich the soil and accelerate the growth of benthic algae. After fertilization, the plankton should bloom within a few days and the color of the water becomes slightly green. The fertilizer, either the organic or inorganic, should be applied daily in the pond at 5-10 % of the initial amount to maintain the plankton bloom. If the plankton has not bloomed within a few days, additional fertilizer must not be applied, but plankton rich water or green water from the reservoir should be added. Aeration A 0.5-1.0 ha pond would require, four aerators installed at the corners of the pond, approximately 3-5 m from the bottom of the dike and positioned at an angle that will encourage the maximum water flow within the pond. The type of aerator to be used depends on the depth of the water. One horsepower paddle wheel aerators should be used in ponds of less than 1.2 m water depth and the 2 HP (horsepower) paddle wheel aerators should be used in ponds deeper than 1.2 m. The most popular type of aerator is the long arm paddle wheel aerator, which is driven by a 2-10 HP electric, or diesel motor mounted on the dike. The aerators should be switched-on 24 hrs before the PL are stocked to allow enough time to create the current and clean up the feeding area.

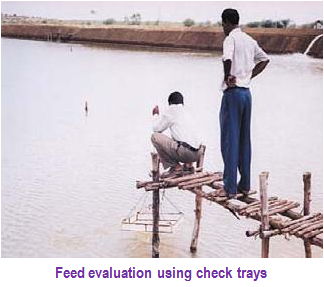

The most suitable species for culture in India are the Indian white prawn Penaeus indicus and tiger prawn P. monodon. The stocking density varies with the type of system adopted and the species selected for the culture. As per the directives of Supreme Court only traditional and improved traditional shrimp farming can be undertaken within the Coastal Regulation Zone (CRZ) with a production range of 1 to 1.5 t/ha/crop with stocking density of 40,000 to 60,000/ha/crop. Outside CRZ extensive shrimp farming with a production range of 2.5 to 3 t/ha/crop with stocking density of 1,00,000/ha/crop may be allowed. Seed selection Selection of good quality seed for stocking into a pond is the first important step of the shrimp grow-out management. The farmer must ensure that he or she gets healthy seed by purchasing them from reliable hatchery or hatcheries. It may not always be possible to obtain the desired shrimp seed due to limitations in availability and quantity. The following parameters should be taken into consideration in purchasing shrimp seed for stocking. (i) Size Seeds of PL 15-20, indicated by the appearance of 4-6 spines on the rostrum, are recommended for stocking in a pond. The healthy PL should have the muscle-to-gut ratio in the sixth abdominal segment of about 4:1 or the thickness of the gut should be about the thickness of the muscle. Practically, seed from the first and second spawning of a broodstock with uniform size can be used. (ii) Morphology The post larvae should have normal appearance of trunk, appendages and rostrum. The abdominal muscle must be clear, no discoloration or erosion on any parts of the body, the gut should be full of food, and the muscle should fill the carapace. (iii) Color Post larvae with the presence of pigment cells in the uropods should be used since this indicates the stage of development. PL that will have high survival and growth rates will be light gray, brown to dark brown and black in colour. Signs of red or pink coloration are normally related to stress. (iv) Behavior Healthy seed swim straight, respond rapidly to external stimuli such as a tap on the side of the basin, actively swim against the current when the water is stirred, and cling to the sides rather than aggregate or be swept down into the center of the container when the current has subsided. (v) External Fouling Seeds should be free from external parasites, bacteria and other fouling organisms. The presence of these organisms indicates unhealthy conditions, which will affect growth and survival of the PL. It is recommended that before purchasing, the farmer should visit the hatchery to check the seed once or twice either in the early morning or late afternoon, especially one day prior to stocking. However, healthy seed with some fouling may be used when the animals are in good condition after treatment. (vi) Pathogen Free Seed should be checked for the presence of viral occlusion bodies. Seed with large numbers of occlusions indicate stress conditions and will not so vigorous in the pond. Stocking Density When a farm is ready for operation, the optimum stocking density of PL in a pond should be determined in accordance with the production capacity of the farm and the culture system, which include the soil and water quality, food availability, seasonal variations, target production, and farmer's experience. It is recommended that farmers should start a new crop with a low stocking density to access the production capacity of the pond. If production is successful, then the stocking density could be increased for subsequent crops. Overstocking should be avoided since it may result in management problems and loss of entire production. The stocking density between 10-20 PL/m2 is usually practiced in a semi-intensive culture. In an intensive culture, a well-managed pond with consistent good water quality can stock up to 25-30 PL/m2 at 1.2 m water depth and up to 40-50 PL/m2 at 1.5 m water depth or deeper. However, it must be emphasized that intensive cultures involve high densities and can only be sustained in well-managed farms under an experienced farmer. Technique of Stocking Proper stocking techniques will prevent unnecessary mortality of seed. The following methods have shown excellent results. (i) Transportation Seed are normally transported in plastic bags. The bags are usually filled up to 1/3 with water, oxygenated and then placed inside styrofoam boxes. If the transportation is longer than 6 hours, small bags of ice should be added into the boxes to reduce the water temperature and maintain it at 20-22oC. The densities of PL in a bag are 1,000-2,000 seed/l for PL 15 and 500-1,000 PL/l for PL 20. The ideal time for transportation is in the early morning or evening to avoid excessively high temperatures during the day, unless a covered vehicle is used. (ii) Acclimation To eliminate stress, the seed should be maintained in water of constant salinity for at least 1-week prior to transfer. The adjustment of salinity by about 3 ppt daily is advisable. Acclimation of seed to the water pH and temperature of the pond must be rendered upon arrival. Two common techniques are used for gradual acclimation of seed to the water conditions in the pond. The first method is accomplished by placing the seed and water from the transported bag into a tank at the side of a pond containing an equal volume of well-aerated pond water. The seed will be kept for 0.5-1 hr before being siphoned into the pond. The second method, the most favorable one, is to float the plastic bag in the pond until it has reached equilibrium. The bags are opened one by one and pond water is added gradually to an equal volume. After a further 30 min of acclimatization, the seed are released directly into the pond by distributing them throughout the area of the pond or into a nursing system. The actual numbers of seed at stocking can be estimated by counting the PL individually in 3-5 bags with a spoon or small net to attain the average number in each bag and multiplied by the total number of bags. (iii) Nursing of Shrimp Post Larvae To ensure high survival and adequate feeding of seed during the first 2-3 weeks, some farms may stock the PL in a separate nursing pond or a small impoundment, usually 5-10 % of the total pond area, within the culture pond. The nursing system will help in concentrating the seed in a limited area until they reach PL 30-40 and in more accurate monitoring for survival and feeding of the PL. However, it appears that the separate nursing pond system may lead to some unfavorable results in that the size of the PL varies widely, (‘broken sizes'), and the seed difficult to harvest and would experience stress during harvest and transport to the culture pond. As a result, a farmer prefers to nurse the seed in an impoundment installed inside the pond, rather than in a separate pond. Recently, some farmers employ a system in which high densities of seed (100-200 PL/m2) are stocked into a pond for 1-2 months, then approximately half of the juveniles are transferred to another pond by large lift nets. The same acclimation process should be performed during seed and juvenile stocking. In a very intensive pond (stocking density greater than 30 PL/m2) where the nursing impoundment is not available, a survival pen may be installed to estimate the survival of the seed during the first 2 weeks after stocking to allow accurate feeding management. The survival pen may be a small net pen or happa of approximately 1 m2 containing 100 seed or a large net pen of usually 10 m2 at 100 PL/m2 stocking density. In the small pen, the seed can be counted accurately while the seed in the large pen may be counted by using a 1 m2 lift net placed with 10% of the feed. In this method, seed should appear in the lift net at 3-4 days after stocking and the number of shrimp in the net should be counted at 2 hours after feeding once daily. The survival number of shrimp can then be estimated. If the survival rate during the nursing period is less than 50%, the problems that cause this initial mortality must be identified and rectified and the addition of more seed should be considered. Seed can be added up to 30 days post-stocking without causing a variation in size at harvest. If the survival is less than 30%, the pond should be drained and prepared for a new crop. Some farmers release seed directly into the pond. In this direct stocking method, the survival number of seed during the first 2 weeks post stocking may not be accurately estimated, since the shrimp will not approach the feeding trays during this period. Cost of feed constitutes a major part of the production cost and accounts for 50% to 70% of the total variable cost. The use of feeds will improve shrimp production and increase profits. The availability of nutrients from feeds depends on the type and quality of the raw material used, the formulation, the feed processing, feed storage conditions and the feeding management. Therefore, feed and feeding practices for semi-intensive or intensive shrimp farming require a basic understanding of nutrition and feed requirements. Shrimp diets may be supplementary or complete. In a extensive system the shrimps need a complete diet. Although natural food items have good conversion values but they are difficult to procure in large quantities and maintain a continuous supply. At present most of the aquaculture farms depend on imported feed with a FCR (Food Conversion Ratio) of 1:1.5 - 1.8. The feeding could be done by using automatic feed dispensers, or by broadcasting all over the pond. If feeding trays are employed in selected pockets in the pond wastage in feed can be reduced.

Nutrient Requirements Shrimp requires approximately 40 essential nutrients. These nutrients are provided in various amounts by natural food and supplemental feeds. Although the nutrition principles are similar for all animals, the quality and quantity of nutrient requirements vary from species to species. The recommended levels of nutrients and dietary components for black tiger shrimp are listed in table below. Recommended nutrient levels for shrimp feed on percentage fed basis

(Source : Lin, 1994) Protein Shrimp consume dietary protein to obtain a continuous supply of amino acids for normal growth. About 20 major amino acids make up most of the proteins and 10 are essential including methionine, arginine, threonine, tryptophan, histidine, isoleucine, leucine, lysine, valine and phenylalanine. Thus, essential amino acids must be provided in adequate quantities and qualities (well-balanced) in the diet. On the other hand, the recommended dietary protein levels for shrimp vary from 30 % to 55 % depending on the shrimp size and species. It is believed that post-larval shrimp require a higher protein level than larger shrimp. Lipid The lipid requirement of shrimp depends on their essential fatty acids and phospholipid content. There are four fatty acids, which are considered essential for shrimp, namely linoleic (18:2n6), linolenic (18:3n3), eicosapentaenoic (20:5n3) and decosahexaenoic (22:6n3). In general, plant oils are high in 18.2n6 and 18.3n3, while the marine animal oils are high in 20:5n3 and 22:6n3. The phospholipid requirement is 2 %; however if lecithin is used this level can be reduced to 1 %. The requirement for cholesterol ranges from 0.25 % to 0.4 %. In addition, the recommended lipid level ranges from 6.0 % to 7.5 % and the level should not exceed 10 %. Carbohydrates The utilization and metabolism of carbohydrates by shrimp are limited. Their type and level in the diet have been shown to affect shrimp growth. Starch as the carbohydrate source is utilized better than dextrin or glucose for Penaeus monodon. Vitamins Little is known about vitamin requirements in shrimp. In intensive farming, vitamins must be supplied in the diet for normal growth. Commercial shrimp feeds are usually over-fortified with vitamins to overcome shortfalls due to processing loss and feed storage. The minimum requirement for vitamin C, which is easily lost, is about 50-150 ppm for Penaeus monodon. Minerals Shrimp can absorb or excrete minerals directly from the aquatic environment via gills and body surfaces. The dietary requirement for minerals is largely dependent on the mineral concentration of the environment in which the shrimp are being cultured. Among the other minerals, phosphorus is the most important, and is recommended at 0.9% as available phosphorus in the diet. Calcium is not considered to be a dietary essential. However, its level in feed needs to be monitored because it is important to maintain calcium to phosphorus ratio of 1:1 to 1:1.5. Calcium should not exceed 2.3% in the diet. Feed Quality The use of good quality feed will improve shrimp production and profits, and minimize the environmental pollution from shrimp farming. The practical indicators of good quality feed are: Feed Conversion Ratio (FCR) An ideal FCR always results in model growth rate, healthy shrimp and clean pond bottom conditions. Only the superior quality of feed can achieve an FCR of 1.2. According to recent data, an FCR as low as 1.2 has been achieved, but many farmers are still obtaining FCRs of higher than 2.2. Therefore, besides the feeding management, the FCR is also closely related to the quality of feed. Attractability The model quality shrimp feed must be highly palatable. Good Water Stability Since shrimp are a slow feeder animal, the water stability of suitable feed should be over 2 hours for Penaeus monodon. Packaging and Optimal Conditions Storage Feed quality will rapidly deteriorate if feed is not packed well and properly stored. Feed should be stored in a dry, cool and well-ventilated place to maintain consistent moisture and temperature. Feed should not be stored in direct sunlight and should not be kept longer than 3 months from the time of processing. The spoiled or old feed should not be used. Feeding Management A high FCR or high amount of feed required to produce unit weight gain indicates overfeeding, and consequently, a poor FCR is usually associated with poor growth rate, low weight gain, stressed shrimp, mediocre water quality and adverse pond bottom conditions. Therefore, the proper amount of feed is the most critical factor of feeding management. The guidelines for feeding adjustment to be made according to the mean body weight of the shrimp are shown in table below. Since many factors are involved in shrimp feed consumption, careful and frequent observation of shrimp is the most reliable approach for determining the optimal feeding amount. There are many major key factors for successful intensive shrimp culture. Use of good quality feed with better feeding management by low feed conversion ratios and improved farm management are the important goals to farmers, not only for gaining greater profit, but also for minimizing the pollution of shrimp farming area. Recommended Feeding Rate for Shrimp Based on Body Weight

(Source : Lin, 1991) Water conditions in the rearing pond deteriorate through the production cycle due to uneaten food, animal's excretion, etc. Generally, shrimp farmers use dissolved oxygen (DO), pH, ammonia, water color and water odor as indicators to judge the water quality of the pond. These parameters are observed regularly by using either scientific equipment or the farmer's experience in order to control them within the optimum range. Optimum water quality for P. monodon pond

Dissolved Oxygen The amount of oxygen dissolved in the pond water is vital to the shrimp's health. However, in the rearing pond, dissolved oxygen is mainly consumed by pond sediment (50-70%) and plankton (20-45%). Only a small portion of dissolved oxygen is consumed by the shrimp (5%). The level of dissolved oxygen can be controlled in 3 ways. Firstly, by increasing the water surface area by means of placing paddle wheels in the right position. This is not only causes proper water circulation, but also adds oxygen to the pond water. Secondly, by controlling plankton density to an optimum level and thirdly, by minimizing excess organic substances, such as uneaten food. pH Adjustment

Water Color Control and Adjustment The color of pond water mainly results from suspended particles of phytoplankton. Plankton density and species are two management aspects that require attention of shrimp farmers. In the first 2 months of shrimp culture, an additional fertilizer either organic (10-30 kg/ha) or inorganic (1-3 kg/ha) is added to the pond in order to ensure that there are enough nutrients for plankton bloom. After this period, nutrients derived from uneaten food normally are at adequate levels. Too many nutrients in some cases may lead to excessive plankton bloom, followed by plankton crash. In an open shrimp culture system the farmers exchange pond water with natural clean seawater to reduce excess plankton density. But in a closed system, where exchanging water is not needed, shrimp farmers use algaecides such as calcium hypochloride or benzalkonium chloride (BKC) 0.1-1 ppm to reduce plankton density. In cases where undesirable water color appears like the ‘red tide' caused by certain types of plankton such as dinoflagellates, the plankton can be controlled by switching-off the aerators for a period of time and applying BKC (0.1-1 ppm). Water Exchange Mass shrimp mortality in a pond associated with deteriorating environmental conditions has occurred frequently during the last 5 years. Shrimp farmers have tried to solve this problem by changing the culture system to a low water exchange system, including partial water re-circulation, full water re-circulation and a closed system. Partial water re-circulation shrimp farming system is practiced where a supply of good quality water may only be available for short periods of time. Normally, the farm area is divided into 4 portions: culture area (60-70%), effluent settlement (10%), mixing reservoir (5-10%), and inlet reservoir (15-20%). In the full water re-circulation shrimp farming system, where seawater can be treated and re-circulated, the farm area is divided into the culture area (40-50%), inlet water treatment (15%), seawater storage reservoir (20-25%) and effluent settlement pond (15-20%). In the close shrimp culture system or zero-water discharge system, no pond water exchange is needed. However, the aeration in the pond must be adequate for shrimp respiration and oxidation of organic waste. Additional seawater may be required to make up for losses in the system. The technique provides disease-free seawater with no effluent being discharged. Shrimp may grow slowly and furnish lower production than those of an open or water circulation system. Successful harvesting can be achieved if the shrimp can be harvested in good condition within a short period of time. The harvesting technique should not damage or excessively contaminate the shrimp with waste. Rapid harvesting will reduce the risk of bacterial contamination and the shrimp will still be fresh when reaching the processor. Complete harvesting can be carried out by draining the pond water through a bag net and hand picking. The average culture period required is around 120-150 days during which time the prawns will grow to 20-30 gm size (depending on the species). It is possible to get two crops in a year. Harvested shrimps can be kept between layers of crushed ice before transporting the consignment to market. Methods of Harvesting Two methods of harvesting are generally practiced on farms. These are either by draining the pond and catching the shrimp in a bag net or by netting the shrimp within the pond. For the first method of harvesting, ponds and outlets should be appropriately designed and be able to completely drain the pond within 4-6 hrs. A bag net should be able to be fixed to the outlet to collect the shrimp that are carried by the out flouring water. The best time for harvesting is early in the morning and it should be completed before mid-morning. In ponds that can only be drained at low tide, the harvest should be conducted whenever possible. The shrimp should be regularly removed from the harvesting bag in small quantities to prevent damage. When netting the shrimp within the pond, either a small electric net or a large seine net can be used. The water level of the pond should be reduced to 0.5-0.75 m deep and workers will need to go inside the pond for netting. This method is less advantageous the pond bottom will be disturbed, thus causing contamination of the shrimp. It is also slower and may take a long time to complete. With either method, it is necessary to hand-pick the remaining shrimp in the pond, after the pond is drained. The harvested shrimp can be quickly killed by giving them a temperature shock (dip in iced water) to prevent damage and to improve storage.  Timing of Harvesting and Selling The timing of harvesting depends on the condition of the shrimp in the pond and also the market price. Shrimps are sampled by a cast net from different areas of the pond to determine their average body weight and general condition. The proportion of soft shell shrimp should not be more than 5% at the time of harvest. This proportion could be obtained by scheduling the harvest halfway between two moultings. The time of moulting is indicated by the presence of exuviae in the pond. For example if the average body weight of the shrimp is 30 gm, then the harvest should be planned for 7-8 days after the exuviae are observed, as the next moulting cycle can be observed after 14-16 days. Harvested shrimp should be iced and transported to cold storage or processing plants in less than 10 hrs. 9. Disease, Prevention and Treatment Cultured shrimps suffer from various diseases due to infectious and non-infectious causes. Infectious diseases are caused by viruses, bacteria, fungi and certain parasites. Treatment cannot be carried out effectively when shrimp diseases occur in a pond. The best way to get rid of diseases is by practicing good farm management or prevention. In this regard, information on various kinds of diseases and their prevention procedures are useful. Infectious Diseases (i) Monodon Baculovirus Disease (MBV) Etiological Agent MBV-type or PmSNPV is a type A occluded monodon baculovirus. Clinical Signs Lethargy, anorexia, poor feeding, dark colouration and reduced growth rate. Infected shrimps are often associated with fouling of gills and appendages by ciliates such as Zoothamnium spp. and Vorticella spp. Acute infection leads to loss of epithelial cells of hepatopancreas. Treatment No treatment available for MBV infection Prevention and Control There is little information on prevention and control of the MBV infection in shrimp pond culture. The prevention method for the MBV infection is possibly through avoidance by screening the PL's before stocking shrimp in the pond. (ii) Hepatopancreatic Parvo-like Virus (HPV) Disease Etiological Agent HPV is caused by a small parvo-like virus, 22-24 nm in diameter. Clinical Signs Reduced feeding, poor growth rate, body surface and gill fouling with ciliates and occassional opacity of abdominal muscles. Severe infections may include a whitish and atrophied hepatopancrease, anorexia and reduced preening activity. Losses may be occur due to the increased occurance of surface and gill fouling organisms and secondary infections by the opportunistic Vibrio spp. Treatment No treatment available for HPV infection. Prevention and Control No information is available on the prevention and control procedures for HPV infection. However, screening the PLs before stocking shrimp by routine histology or the Giemsa-impression smear method is recommended. (iii) Yellow-head Disease (YHD) Etiological Agent Yellow-headed virus (YHV) is a ssRNA, rod shaped, enveloped virus with two rounded ends. Clinical Signs The affected shrimp shows a marked reduction in food consumption. Following this, a few moribund shrimp will appear swimming slowly near the surface of the pond dike and remain motionless. The animals have pale bodies, a swollen cephalothorax with a light yellow to yellowish hepatopancreas and gills. A high mortality rate may reach 100% of affected populations within 3-5 days from the onset of disease. Treatment No treatment is available for YHV infection. Prevention and Control The reliable method to prevent the occurrence of YHD is possibly through avoidance, such as careful selection of post larvae, reduction or elimination of horizontal transmission including carriers, disinfection of contaminated ponds or equipment with 30 ppm; and chlorine, providing shrimp with good waterquality and proper nutrition.

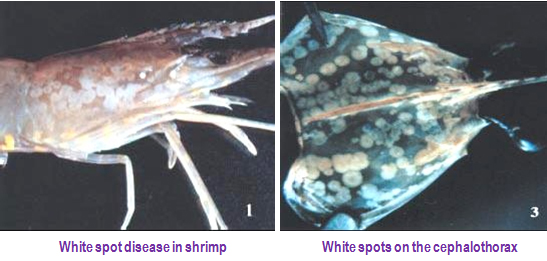

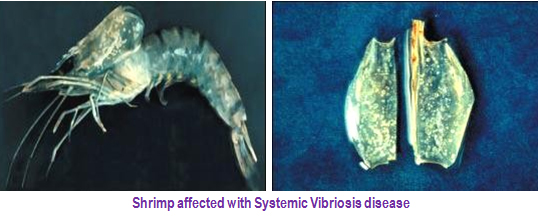

(iv) White Spot Disease (WSD) Etiological Agent The disease is caused by the dsDNA virus, Systemic Ectodermal and Mesodernal Baculovirus (SEMBV). Diagnosis Procedure The diagnosis procedure of SEMBV infection is based on the appearance of the intranuclear hypertrophy in stained histological sections and the presence of virus particles in the nucleus of the infected cells observed under the electron microscope. PCR technique is recently used to detect SEMBV in shrimp larval and other stages, including broodstock and subclinical virus carriers. Treatment No treatment is available for SEMBV infection. Prevention and Control Prevention practices through avoidance are strongly recommended for the farmers, involving the combinations of efficient pond management, use of proper feed, selection of good quality of PL, reduction of possible carriers, avoidance of introduction of contaminated water into the pond, and disinfection of all equipment and utensils.  (Source: FAO technical paper) (v) Infectious Hepatopancreatic and Lymphoid Organ Necrosis (IHLN) Etiological Agent The primary cause of the disease is attributed to viral etiology. Clinical Signs Light pinkish to yellowish discolouration of the cephalothorax region. Often fouling by ciliate protozoan Zoothamnium seen. Blackened and necrotic hepatopancreas. Secondary bacterial infection from bacteria such as Vibrio alginolyticus seen. Treatment No treatment is available for IHLN infection. Prevention and Control Keep the physico-chemical condition of pond environment within acceptable levels. To avoid bacterial and viral pathogen entering from outside, closed culture could be useful in prevention of IHLN disease. (i) Luminous Vibriosis Etiological Agent Vibrio harveyi, Vibrio vulnificus Clinical Signs High mortality rate in young juvenile shrimp (one month syndrome). Moribund shrimp hypoxic often come to the pond surface and edges of pond. Vertical swimming behavior immediately before onset of acute mortality. Presence of luminescent shrimp in ponds. Treatment Disinfection of intake water with Formalin (100-200 ppm). Administration of Oxolinic acid (0.6 ppm) and Sarafloxacin (5mg/kg) through feed for 5 days. Prevention and Control Proper pond and water management. Utilization of reservoir for intake water. (ii) Vibriosis Etiological Agent Vibrio vulnificus, V. parahemolyticus, V. alginolyticus, V. anguillarum, V. damsella, V. fluvialis and V. mimicus. Clinical Signs High mortality rates, particularly in young juvenile shrimp. Moribund shrimp with corkscrew swimming behavior appear at edge of pond. Reddish discoloration of juvenile shrimp. External Fouling Black spots, chronic soft shelling. Treatment Disinfection of intake water i.e. formalin 100-200 ppm. Anti-microbial preparation application through feeds (Oxolinic acid 0.6 ppm and Sarafloxacin 5 mg/kg). Prevention and Control Proper pond and water management and utilization of reservoir for intake water.  (i) Larval Mycosis Etiological Agent Filamentous fungi of genus Lagenidium spp. and other filamentous fungi, such as Sirolpidium spp. and Haliphthoros spp. Clinical Signs Eggs and larve are weak and appear whitish. Moratlities may reach 100% within two days. Fungal mycelium replaces the larval tissues and ramifies into all parts of the body and protrudes out of the body and develops into sporangia. Prevention and Control General hatchery management practices such as use of UV sterilised and filtered seawater, adequate water exchange etc., must be strictly followed. Rearing water, equipment used in the hatchery and all hatchery facilities must be thoroughly disinfected before retarting the hatchery operations. D. Protozoan and Parasitic Infestation (i) Black Gill Disease Etiological Agent Fusarium spp Clinical Signs Brownish to blackish discoloration on the gills of juvenile shrimp. Treatment No treatment is available for fungal infestation without harming the shrimp. Prevention and Control No information on prevention and control. However, good management of the pond bottom and prevention of the entry of wild crustaceans into the pond, which may carry pathogen, can be effective control practices.

(ii) Surface Fouling Diseases Etiological Agent Many species of bacteria, algae and protozoa such as filamentous bacteria, Leucouthrix sp., Flavobacterium sp. and Zoothamnium sp. Clinical Signs Infected shrimps show black/ brown gills or appendage discoloration or fuzzy/cottony appearance due to a heavy colony of the organisms. In some cases, the severely affected shrimp die during the molting period. Treatment Chlorine and formalin are often used to treat those commensal organisms if shrimp display heavy infection. Changing water is the most preferable management, which stimulates molting of the shrimp in order to reduce the infestation. Prevention and Control Prevention and control of the occurrence of surface fouling are usually done through maintenance of good sanitary conditions at the pond bottom and the overall pond area. Organic matters and suspended solids in the pond should be reduced to prevent the attachment of those fouling organisms. This is achieved by changing the water or applying lime. (iii) Microsporidosis (Cotton shrimp disease or Milk shrimp disease) Etiological Agent Microsporidia such as Thelohania spp., Nosema spp., and Pleistophora spp. Clinical Signs Infected shrimps appear opaque and cooked. Gradual and low levels of mortalities are observed. Microsporidia invade and replace gill, muscle, heart, gonads and hepatopancreas, and cause necrosis in these regions. Prevention and Control Maintain of good sanitary conditions at the pond bottom and the overall pond area.  (Source: CIBA Extension Series) (i) Soft-shell syndrome Etiological Agent The exact cause of soft-shell syndrome is not known. However, low saline condition in the culture pond and deterioration of pond bottom condition are some physico-chemical factors that causes this disease. Shrimps fed with low protein diet, contamination through agricultural run-off, high soil pH, low water phosphate and low organic matter in soil all have an impact on soft-shell disease. Clinical Signs Shrimps are weak, usually off-feed, have a loose thin exoskeleton. Rostrum is stiff as healthy shrimps. Wavy undulating intestine is clearly visible. Prevention and Control Low stocking density, feeding with high quality feed and frequent water exchange are likely to reduce the recurrence of the disease.

Before harvesting and/or exporting, shrimp should be examined for their health, hygienic quality and safety for consumers. Unhealthy shrimps, which are easily recognized through their appearance, will not be acceptable to consumers and market value could be reduced. Unhealthy shrimp should be treated before harvesting or removed during harvesting and processing if the proportion of unhealthy shrimp in the stock is low. Human pathogenic organisms could contaminate the shrimp during harvesting, storage and processing. Therefore, samples of shrimp should be sent to a reliable laboratory to conduct necessary test to certify the hygienic quality of the products, before exporting or sending them to market. The harvested shrimp should also be checked for antibiotics and heavy metal residues before export. If the shrimp have been treated for unhealthy conditions with antibiotics, the recommended withdrawal period should be followed. Banned Antibiotics, Pesticides and Pharmacologically Active Substances

(Source: MPEDA & NACA Manual 2003) (Source:Photos courtesy: Shrimp Health Management Extension Manual- MPEDA & NACA www.fishdb.sinica.edu.tw) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

© All Rights Reserved. TNAU-2014. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||